My Name is N. Srivathsan, a native of Tamil Nadu. My Father is a retired Middle school Headmaster. Mother is a Home Maker. I have a younger brother and a younger sister. My Wife is an MCA Graduate who is currently not working. My daughter is into her 10th grade. I Passed out B. E – Instrumentation and control from Madras University in 1997. I worked for Industrial process control-related erection and commissioning and Plant Maintenance organizations.

Starting from 2003 working for Yokogawa, Bangalore, I have traveled to Singapore, China, USA, UAE countries and executed various global megaprojects through design, Engineering, site commissioning, Project Management, and Operation Management. I hold a Six sigma green belt, PMP, PMI-CDP certification.

My Current designation is “Executive Manager,” and heading operations related T&D department.

I was in Project Execution Management for global projects at Yokogawa Bangalore while joining the PGP-AIML Online Program.

In the Industrial Environment, poor alarm management will lead to a lot of nuisance alarms and will impact the operator’s ability to do their plant monitoring and control job. This may become the primary cause of Industrial accidents and loss of production. Due to lack of guidance during the audit in running Industry, during design & Engineering stage, it will cause impediments to controlling room operator decisions about which alarms to address first during alarm flooding blitz.

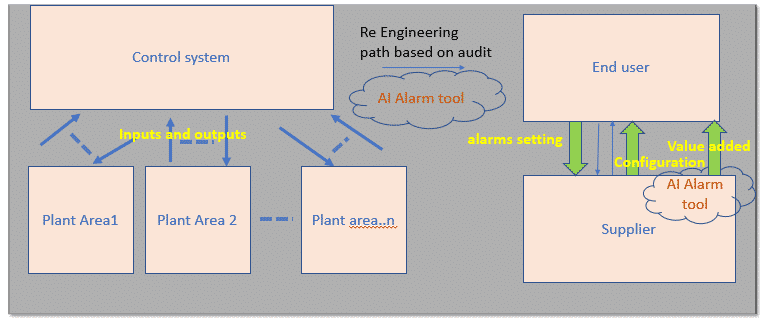

In the Industrial Environment like Oil & Gas, Petrochemical, etc., various processes and related controls are involved in maintaining parameters like temperature, pressure, level, etc., in yielding a good quality product. Thousands of inputs and outputs from the field get connected to the control room System called distributed control system. The plant operator (End-user) monitors and controls the parameters from the control system.

Alarm settings to be configured for the Process control loops are usually bundled with the control loops database after the study on giving operators an alert and guidance to take appropriate actions during abnormal conditions. If the alarms are not rationalized (meaning optimizing the number and quality of alarms that the control room operator needs to respond properly during normal operations and process upsets) properly, an operator will not be able to prioritize the alarms and will end up in obscured situation causing loss of production and personnel damage.

Also, various hazardous operations studies are done by End-users to design an alarm but miss out on the Pragmatic approach towards validating the alarms during an audit and during the plant operation.

Various Industrial accident reports drill down to the cause of Poor alarm Management. Guidelines are set by ISA/IEC standards for alarms management. However, obtaining funding for an alarm rationalization is difficult due to the time and resources required. Control system suppliers end up in default configurations due to a lack of inputs and reengineering at a later stage.

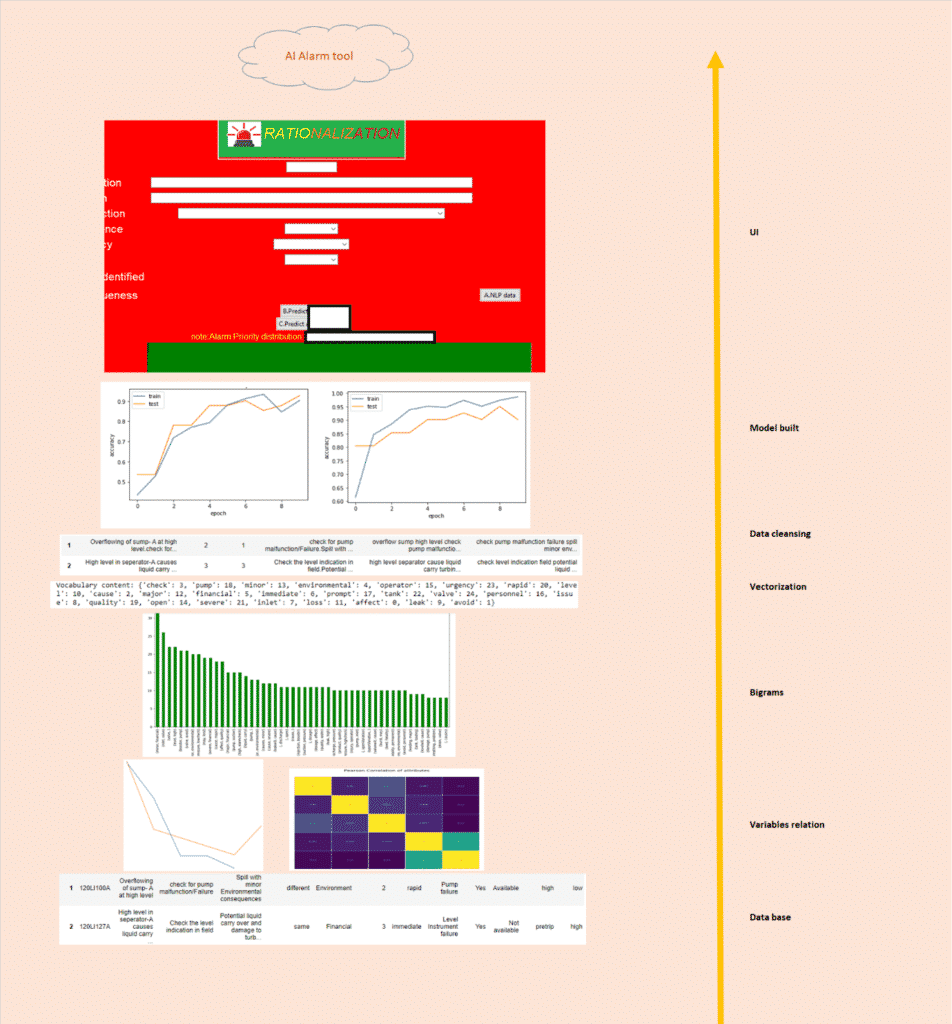

Several analyses and methodologies are followed for Alarm Management. But an AI-based model to train on the consistent criteria in order to remove nuisance alarms, Setting and prioritizing the alarms, it is very important to have data with all possible combinations. The Industrial data set for alarms is not easily available as an open-source. Also, data from the actual source will not have all combinations. So complete manual audit is done to prepare data based on manual recommendations by Experts.

People with domain knowledge set the alarm rationalization based on their industry experience and knowledge of standards. But in order to generalize the predictions and at the same time to implement the guidelines set by Standards, the NLP model is identified as a better option as it predicts based on just a few keywords.

The ten key Predictor variables are not correlated to each other. But only the combination of these variables will help in predicting the two target variables. The two target variables are also not related to each other. The vectorization is done with appropriate combinations for better predictions.

Oversampling is done for better accuracy as the database size is not bigger enough.

To design an AI tool that can recommend End users about the alarm rationalization based on certain key input data during the design and engineering phase, alarms can be configured effectively. This tool can also be beneficial in the running Industry during an audit.

The return on investment to End users related to the long-term benefits:

● With the right alarm at the right time, operators can take action to ensure the operation remains within the desired operating range

● Operators can make decisions to prevent shutdowns and incidents

● Many insurance companies require companies to adhere to industry standards and best practices to qualify for reduced insurance rates

The benefit to the Control system Supplier is a value-added service, avoiding Reengineering (approximately 10 to15% of project cost) and accelerating the growth of customer relationships.

While we try to understand the basic concepts through an AI model built using real-time data available as an open-source, the thought process towards implementing it in the domain expertise I belong to help in visualizing the domain concepts and viewing AI concepts through domain knowledge lens.

Position of AI tool

Data analysis and AI Model flow: